Tarpaulins, also known as tarps, are flexible sheet materials designed to protect against various environmental factors, including rain, sunlight, wind, dust, and mechanical damage. Tarpaulins are widely used in various applications, including agriculture, construction, transportation, disaster relief, and household use. From a materials science perspective, a tarpaulin is not a simple plastic sheet, but a composite material whose performance depends on polymer chemistry, fiber structure, coating technology, and environmental resistance. Understanding these factors also explains why inexpensive tarpaulins deteriorate much more quickly than high-quality ones.

1. Materials used in tarpaulins

1.1 Polyethylene (PE)

The most common material used in low to medium-cost tarpaulins is Polyethylene, particularly HOPE(High-Density Polyethylene) or LDPE (Low-Density Polyethylene).PE is a thermoplastic that contains a chain of carbon and hydrogen atoms. Since it is nonpolar, it is waterproof due to its nature.HOPE contains high crystallinity, providing higher tensile strength compared to LDPE.

1.2 Polyvinyl Chloride (PVC)

PVC tarpaulins are used for heavy-duty and industrial purposes. It contains chlorine atoms that increase intramolecular bonding. Better resistance to chemicals, UV radiation, and abrasion. More flexible over a wide temperature range.

1.3 Canvas and Polyester fabrics

Canvas tarpaulins are made from cotton or polyester fabric with waterproof coatings. Natural fibers are hydrophilic and absorb water. Coatings such as wax, acrylic, or PVC are required for waterproofing.

2. Woven Fiber Structure and Mechanical Strength

Most plastic tarpaulins are manufactured by weaving thin polymer tapes in two perpendicular directions, called warp and weft. Woven structures distribute tensile strength due to better load transfer. High-quality tarps use uniform, tightly woven fibers. Poor weaving results in uneven stress distribution, making the trap prone to tearing.

3. Coating lamination and technology

After weaving, tarpaulins are laminated or coated on both sides. The coating acts as a barrier layer, preventing better penetration and slowing oxidation and UV-induced chain scission in polymers.

4. Thickness, GSM, and Durability

4.1 Thickness (Microns)

Thicker tarpaulins resist puncture and tearing better. Thin sheets fail under mechanical stress.

4.2 GSM( Grams per meter square )

GSMindicates material density. Higher GSM means more polymer mass and higher mechanical strength. From a material science viewpoint, higher GSM equals more polymer chains per unit area, resulting in a better load-bearing capacity.

5. UV degradation mechanism.

Sunlight is the biggest enemy of tarpaulins. UV radiation breaks polymer chains ( photooxidation). This reduces molecular weight. Material becomes brittle, discoloured, and cracked. UV stabilizer such as HALS ( Hindered amine light stabilizers ). Carbon black pigments that absorb UV radiation.

6. Thermal behaviour of tarpaulins.

Trapaulins are thermoplastics, so temperature greatly affects their behavior. High temperature softening, stretching, and deformation. Low temperature reduced flexibility and cracking. This happens due to changes in polymer chain mobility.

7. Failure Mechanism of Tarpaulins

- Tensile overload

- Puncture by sharp objects

- UV degradation

- Creep under constant load.

- The destination between fabric and coating

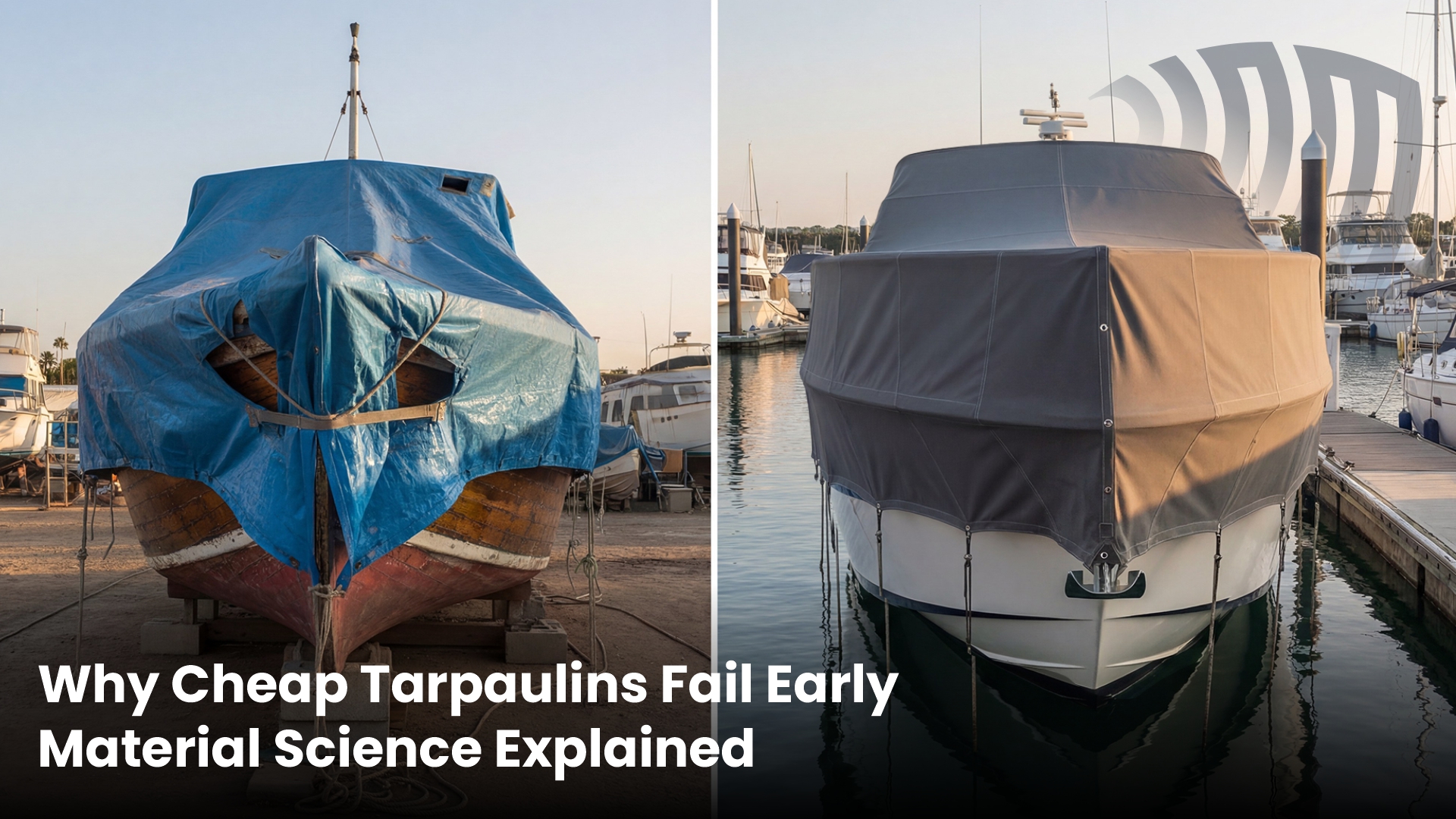

Why cheap tarpaulins fail early.

1 Use of Recycled or low-grade plastic.

Cheap tarpaulins are commonly manufactured using recycled or low-grade polymers. Instead of virgin polymers. Recycled polymers contain impurities, contaminants, and degraded chains. Lower molecular weight results in reduced tensile strength and elasticity. Weak intermolecular bonding causes microcracks, which grow under stress. Polymer chains become shorter, reducing molecular weight.

2 Low GSM and thin fibers

GSM indicates the mass of material per unit area, which directly relates to strength. Cheap tarpaulins use LOW GSM fabric. Thin fibers carry less mechanical load. Under wind pressure, rain load, or tension, fibers break easily. Reduced thickness lowers abrasion and puncture resistance.

3 Poor fiber orientation and loose weaving.

High-quality tarpaulins use uniformly oriented and tightly woven fibers. Cheap tarpaulins have random fiber alignment. Loose weaving creates stress concentration points. When force is applied, stress is not distributed evenly. Small tears rapidly propagate along weak paths.

4. Inadequate or No UV Stabilizers

Polymers are highly sensitive to ultraviolet (UV) radiation. UV rays break carbon - carbon bonds in polymer chains. Without UV sta

Bilizers, photodegradation occurs rapidly. Materials become brittle and chalky. Color fading indicates chemical degradation. Surface cracks develop within months of sun exposure.

5. Weak coating and Poor lamination

The coating protects the woven fabric from water, chemicals, and UV radiation. Cheap tarpaulins use thin, uneven coatings. Poor adhesion between fabric and coating causes delamination. Peeling exposes fiber to moisture and sunlight. Water leakage starts at peeled regions.

6. Thermal Insatability

Polymers expand and soften at high temperatures and become brittle at low temperatures. Cheap tarpaulins lack thermal stabilizers. In hot climates, material softens and stretches permanently. In cold conditions, it cracks due to brittleness. Repeated thermal cycling accelerates material fatigue.

7. Absence of protective additives

.

To reduce cost, manufacturers skip important additives:

- Antioxidants- prevent oxidation

- Antifungal agents - stop mold growth.

- Fire retardants - reduce fire risk

Conclusion:

From a material science perspective, a tarpaulin is a layered polymer composite system. Its durability depends on polymer purity, molecular structure, fiber orientation, coating quality, stabilizers, and GSM. Cheap tarapalins fail early because manufacturers compromise on all these scientific parameters to minimize cost. Understanding these material principles helps users select tarpaulins that offer long-term performance, safety, and cost efficiency.